Powering Traffic Control Vehicles with Reliable Dual Battery Systems. Discover how a dual battery system powers traffic control vehicles, ensuring reliable arrow boards and warning lights. Learn about AGM and Lithium batteries, under-tray mounting, and proper charging to avoid dead batteries at worksites.

Maximize Safety and Reliability with a Dual Battery System for Traffic Control Vehicles

Traffic control vehicles are critical for road safety, stationed at worksites to direct traffic and protect workers with essential warning devices like arrow boards and warning lights. These vehicles often remain stationary for extended periods, placing heavy demands on their electrical systems. A dual battery system, complete with a circuit breaker and a dedicated DC-DC charger, is the ultimate solution to ensure reliable power and uninterrupted operation. Here’s why equipping your traffic control vehicle with a dual battery system, advanced battery technology, and proper installation is a must.

The Power of a Dual Battery System

A dual battery system features a primary battery dedicated to starting the vehicle and running core systems, paired with a secondary battery designed to power high-demand accessories like arrow boards, warning lights, and other traffic control equipment. This setup delivers key advantages:

- Uninterrupted Power for Warning Devices: Arrow boards and warning lights are vital for visibility and safety at worksites. A dual battery system ensures these devices run consistently without draining the primary battery, preventing the dreaded dead battery when it’s time to pack up—especially in the middle of the night on a busy road.

- Prolonged Operation at Stationary Worksites: Traffic control vehicles often sit idle for hours, powering warning devices without the engine running continuously. The secondary battery provides a dedicated power source, supporting extended use of accessories while preserving the primary battery’s charge for starting the vehicle.

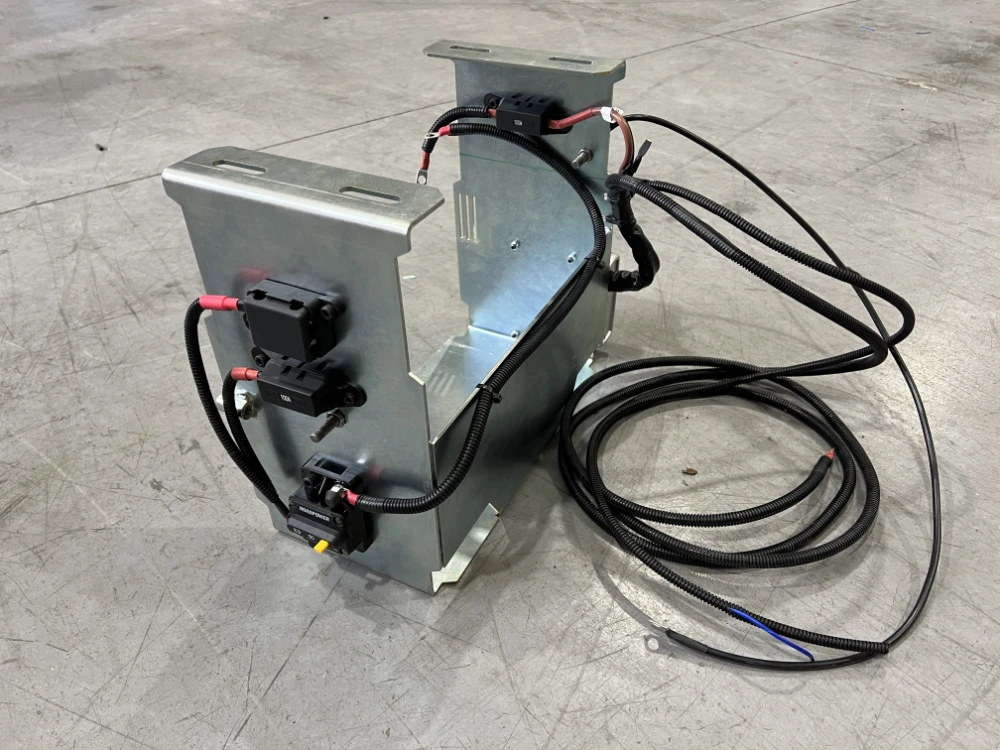

- Enhanced Safety with Circuit Breaker Protection: Our dual battery systems include a circuit breaker in the under-tray assembly, which isolates the arrow board and warning lights. This protects the system from electrical faults, ensures stable operation, and adds an extra layer of safety for your equipment and crew.

Optimal Charging with a Dedicated DC-DC Charger

To keep your dual battery system performing at its best, sufficient recharging time is essential, but relying solely on the vehicle’s alternator is no longer best practice—especially with newer vehicles equipped with smart alternators. These alternators adjust output based on driving conditions, which can lead to inconsistent charging for the secondary battery. Instead, we recommend using a dedicated DC-DC charger. A DC-DC charger ensures a stable and appropriate charging voltage for the auxiliary battery, preventing overcharging or undercharging, which can damage it. This is particularly important during transit to and from worksites, where the charger optimises battery health and performance.

For vehicles that don’t commute enough, the dual battery may not have sufficient time to recharge fully. In such cases, drivers should regularly check the battery’s charge level and use an external charger if needed to maintain optimal performance. Plan routes to allow adequate driving time for charging, and for vehicles with shorter commutes, a DC-DC charger provides peace of mind by maximising charge efficiency.

Advanced Battery Technology: AGM and Lithium

Choosing the right battery technology is critical for maximising the performance of your dual battery system. Traditional lead-acid batteries are being surpassed by advanced options like Absorbed Glass Mat (AGM) and Lithium-ion batteries, which offer superior reliability for traffic control vehicles.

- AGM Batteries: AGM batteries are sealed, maintenance-free, and highly resistant to vibration and shock, making them perfect for rugged worksite conditions. They excel in deep-cycle applications, handling repeated discharges (like powering warning lights) without losing capacity. Plus, they pair well with DC-DC chargers for efficient recharging.

- Lithium-ion Batteries: Lithium batteries offer higher energy density, lighter weight, and longer lifespans. They can endure more charge-discharge cycles, making them ideal for demanding applications like arrow boards. When paired with a DC-DC charger, lithium batteries maintain peak performance, though their higher upfront cost is offset by long-term durability.

Both AGM and lithium batteries provide unmatched reliability and efficiency, ensuring your warning devices stay powered throughout long shifts.

Strategic Mounting for Optimal Performance

The placement of your dual battery system is just as important as the technology itself. Traffic control vehicles often operate in high-heat environments, especially when stationary at worksites with limited airflow. That’s why we mount the secondary battery under the vehicle’s tray in the open. Unlike the engine bay, where heat from the engine can accumulate and reduce battery lifespan, an under-tray location benefits from better ventilation and cooler temperatures. This is especially critical for AGM and lithium batteries, which are sensitive to extreme heat.

The under-tray assembly also includes a circuit breaker, which isolates the arrow board and warning lights, protecting the system from electrical issues and enhancing safety. The battery, circuit breaker, and DC-DC charger are securely housed in a vibration-resistant enclosure to withstand road debris, moisture, and tough worksite conditions. This setup simplifies maintenance and inspections, keeping your vehicle ready for action.

Conclusion: Power Your Worksite with Confidence

For traffic control vehicles, a dual battery system with a circuit breaker and a dedicated DC-DC charger is a necessity, not an option. By providing a dedicated power source for arrow boards and warning lights, it ensures safety, reliability, and efficiency at stationary worksites. Advanced AGM or lithium battery technology boosts performance, while under-tray mounting with a circuit breaker and DC-DC charger protects the system from heat, electrical faults, and improper charging. Allow sufficient recharging time during transit, and ensure drivers check and externally charge the battery if commutes are too short.

Invest in a dual battery system to eliminate the risk of a dead battery and keep your worksite safe and visible. Contact our team to design and install a custom dual battery system tailored to your traffic control vehicle’s needs, complete with AGM or lithium batteries, a circuit breaker, and a DC-DC charger for maximum reliability.

Ready to upgrade? Reach out to our experts today to explore your options and keep your traffic control vehicle powered up and ready for any challenge. Stay safe, stay lit, and keep the roads secure!